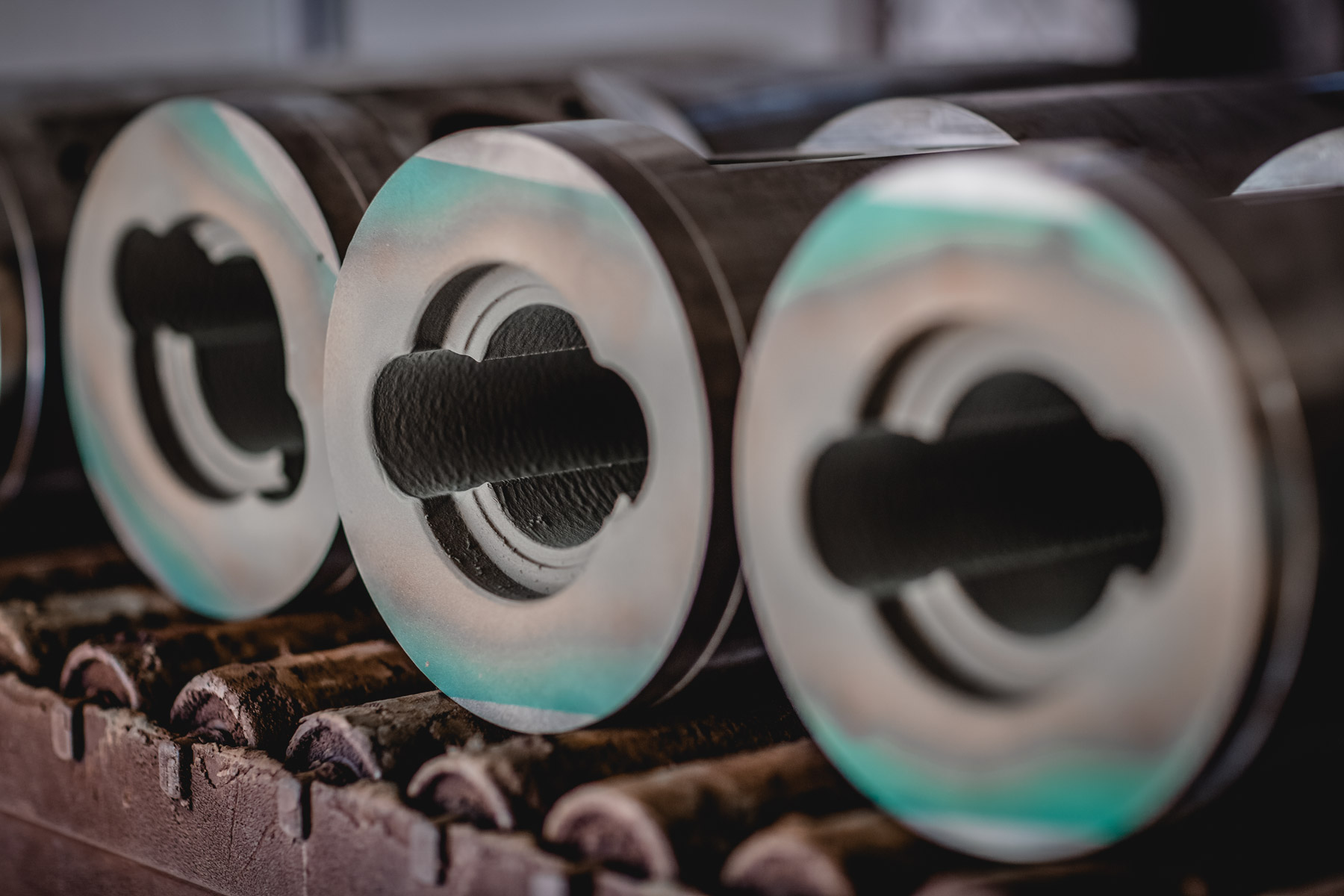

Corrosion protection

For over 40 years, the thin-film composites ZSV 216 and ZSV 111 have proven their worth as powder coating materials for metallic substrates to prevent fretting corrosion / fretting corrosion and as corrosion protection.

The thin-film composites ZSV 216 and ZSV 111, with an applicable coating thickness of 200-300 µm, are suitable for the following problems:

1. fretting corrosion

This type of damage is known as “fretting corrosion” or “bleeding”. The result is a fatigue fracture. The following process takes place:

If two metallic materials are joined together in a force-transmitting manner and they move against each other in an oscillating manner, even if only in the range of their respective elastic deformability, then the finest fatigue fractures can occur at the local force-transmission locations, leading to the breaking out of the finest material particles. The fracture surfaces are highly active at the moment of their formation and react, for example, with atmospheric oxygen (oxide formation), with nitrogen (nitride formation) or carbon (carbide formation). Since the resulting reaction products are more voluminous than the original material, they require space and lead to tensile stresses in the phase boundary between the two partners. This tension can cause fatigue fracture.

2. corrosion protection in a variety of critical media

Corrosion is defined as “the reaction of a metallic material with its environment that can cause a measurable change in the material and lead to impairment of the function of a metallic component or an entire system.”

However, with ZSV 216 as well as ZSV 111, an optimum problem solution is possible for all requirements. The coating can be applied internally or externally and up to a max. layer thickness of 1 mm and can then be machined using all common machining techniques.

Coating technology specialist

If you would like more information, also about other coatings, simply contact us.